Have you ever struggled to get clean, accurate cuts on tough materials? Whether you’re working with wood, metal, or plastic, precision can feel just out of reach.

That’s where advanced laser technology comes in. It’s changing how people cut, shape, and create-saving time, reducing waste, and boosting quality. With laser tools, your cuts aren’t just close-they’re exact.

This article will show you why laser cutting is the smart choice. If precision matters, you’re in the right place.

Precise Beam Control

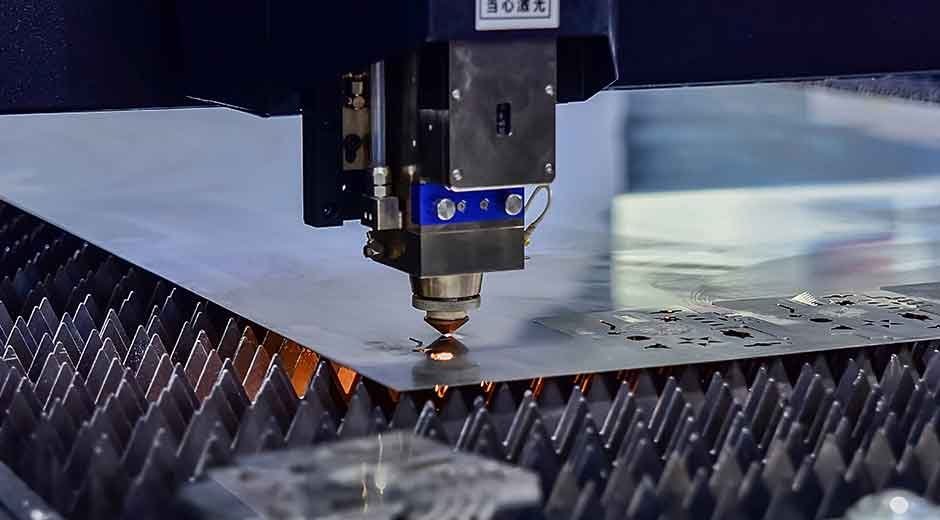

Advanced laser systems use a narrow and stable beam to follow exact programmed paths. This control allows cutting materials with fine detail. Each pass of the laser is intentional and consistent.

The steady beam avoids shifting or wobbling during the process. This reduces flaws and keeps the shape accurate. Even over long production runs, the cuts stay sharp and reliable.

Minimal Material Waste

Laser cutting reduces extra cuts by using highly targeted heat. This ensures that only the necessary areas are cut, without damaging the surrounding material. Each project uses just the right amount of raw material.

Because less material is wasted, production costs go down over time. Scrap is reduced, which also helps with storage and clean’up. Efficient use of materials helps both the environment and the budget-reducing material waste.

Multi-Material Compatibility

Laser cutters can work on metal, plastic, wood, and other materials. Settings are adjusted based on the type of material. This makes them useful for many industries.

Industries rely on cutting tools offering flexibility and precision. Laser cutting is preferred due to its ability to handle various materials effortlessly and accurately. One machine can do several jobs without needing extra tools. This saves space and reduces machine costs. It also simplifies training for workers.

Reduced Human Error

Laser systems rely on pre-programmed digital inputs rather than manual control. Operators set up the design once, and the machine follows it exactly. This helps prevent common mistakes with hand tools.

Once the laser starts cutting, it performs the task without distractions or fatigue. Each pass is identical. This builds trust in the outcome and lowers the need for rework.

Faster Production Speeds

Laser cutters move quickly across surfaces without losing accuracy. They can finish complex jobs in much less time than manual tools. This speed makes a significant difference in high-volume production.

A faster cutting process means quicker delivery to customers. It helps maintain schedules, even with increased orders. This efficiency also reduces the cost per unit made.

Consistent Cutting Quality

Every time the laser cuts, it produces the same high-quality result. The lines stay clean, and the depth stays exact. This uniformity is important in industries that demand high standards.

Customers can count on receiving products that match each time. It also reduces the need to inspect each piece closely. Fewer flaws mean fewer returns or complaints.

Cleaner Edges and Finishes

Laser cutting leaves behind clean, sharp edges with no rough spots. The material doesn’t crack, bend, or tear during the process. The result looks finished right away.

With no need for sanding or polishing, time is saved. Smooth edges also make parts easier and safer to handle. The final product looks professional without extra steps.

Enhanced Automation Options

Laser systems work well with automated software and machines. They can be part of a larger production line with little need for manual input. This allows continuous operation during long shifts.

Automation also allows one person to manage multiple tasks efficiently. Fewer hands are needed to keep things running. That leads to better use of labor and lower costs.

Better Use of Complex Designs

Lasers can follow very detailed patterns from digital files. Even shapes with small curves and tight corners are easy to cut. This supports more advanced design needs.

Designs don’t need to be changed or simplified. The machine follows the exact plan without missing any details. It helps bring creative ideas into real products with no loss in precision.

High Repeatability

Laser cutting systems can repeat the same process over and over with no shift in quality. This is useful in making parts that need to match exactly. It ensures that every item meets the same standards.

High repeatability minimizes surprises during production. It helps with quality checks and smooths out assembly steps. Workers can rely on every piece being right the first time.

Reduced Downtime

Laser machines run for long hours without breaking down. Their design avoids the wear and tear that affects tools with blades and motors. Less wear means fewer interruptions.

Fewer pauses for repairs help meet deadlines. It also allows for better planning in the workflow. Increased uptime enhances overall productivity.

Lower Risk of Tool Damage

Lasers cut without direct contact, which means no tool hits the material. There are no blades that can break or dull. This makes the system more durable and reliable.

Because tools aren’t wearing out, maintenance becomes simpler. Repair costs decrease. The machine stays ready to work when needed.

Improved Safety Conditions

Laser machines are built with protective barriers and control systems. These features prevent direct exposure to the beam. Workers stay safe while the machine operates.

Most systems also include sensors that stop the machine if something goes wrong. This adds an extra layer of safety. A safer work environment lowers the chances of accidents and keeps production steady.

Lower Long-Term Costs

Laser cutting systems may cost more initially, but they save money over time. Their high accuracy and low waste reduce the need for extra materials. They also cut down on labor costs through automation.

Because repairs and maintenance are less frequent, there are fewer surprise expenses. Energy use is also more efficient in many modern systems. Over time, these savings add up and improve profit margins.

Cutting Edge Results With Every Beam

Precision matters, and laser technology delivers it with power and consistency. It helps professionals and hobbyists alike get more done with less effort. When tools work smarter, projects stand out.

Don’t settle for guesswork or uneven results. Choose a method that meets your highest standards every single time.

Did you learn something new from this article? If so, be sure to check out our blog for more educational content.