Introduction

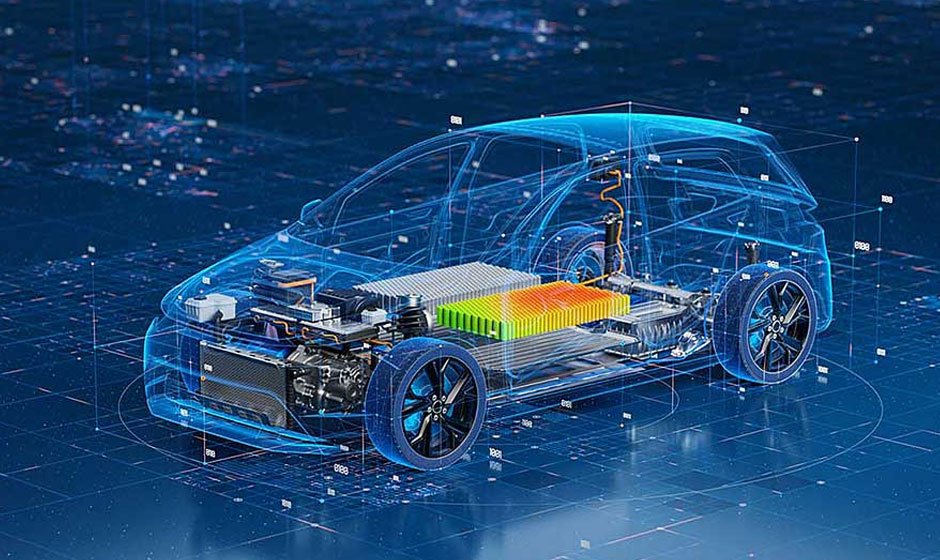

As the world shifts towards sustainability, the electric vehicle (EV) industry is at the forefront of innovation, pushing boundaries in design, efficiency, and performance. One of the key challenges EV manufacturers face is finding ways to increase vehicle range while maintaining safety and durability. A crucial solution lies in lightweighting—reducing the overall weight of EV components to improve energy efficiency. In this regard, rubber calendering technology has emerged as a game-changer, playing a significant role in optimizing key components while maintaining performance and safety standards.

Crowns Machinery, a leader in rubber equipment manufacturing, is pushing this transformation forward with their advanced Rubber Calender Machine, contributing to the development of lighter, stronger, and more durable components for the EV industry.

The Role of Rubber in EV Lightweighting

Electric vehicles rely heavily on rubber for various components, such as tires, seals, insulation, and gaskets. These parts are critical to the overall performance, safety, and comfort of the vehicle. For example, EV tires must provide low rolling resistance to improve energy efficiency, while seals must ensure that the vehicle is well-insulated to avoid noise pollution and maintain aerodynamics.

However, as EV manufacturers look to reduce vehicle weight to extend driving range, the challenge lies in making these rubber components lighter without compromising their performance. This is where rubber calendering technology comes into play.

How Rubber Calendering Technology Enables Lightweighting

Rubber calendering is a process that involves passing rubber through a series of rollers to achieve precise thickness and uniformity. This highly controlled process is essential for creating thin yet durable sheets of rubber that can be used in a variety of EV applications.

Here’s how rubber calendering technology supports lightweighting in EVs:

Precision in Material Thickness: The ability to control the thickness of rubber sheets allows manufacturers to reduce the weight of components without sacrificing their strength or durability. For example, thinner yet stronger rubber gaskets can provide the same level of insulation while weighing significantly less. This reduction in material use helps lighten the overall weight of the vehicle.

Enhanced Material Properties: Modern rubber calender machines, such as those developed by Crowns Machinery, are capable of producing rubber with enhanced properties. By controlling the material during the calendering process, it’s possible to increase the tensile strength and flexibility of the rubber, ensuring that even lightweight components can withstand high stress and maintain their performance under various conditions.

Uniformity for Better Efficiency: Uniform rubber sheets are critical for ensuring that EV components perform consistently over time. By producing rubber with exact thickness and uniformity, manufacturers can reduce the likelihood of uneven wear and tear, thereby extending the lifespan of critical parts like tires and seals. This contributes to the overall reliability of electric vehicles, allowing for lighter components without sacrificing quality.

Integration of New Materials: With the increasing focus on sustainability, many EV manufacturers are exploring the use of eco-friendly materials in their vehicles. Rubber calendering technology can help process new, lightweight materials such as recycled rubber, bio-based rubbers, or other eco-friendly compounds, ensuring they meet the required performance standards. Crowns Machinery’s innovative Rubber Calender Machine is designed to handle a variety of materials, making it an ideal solution for manufacturers looking to reduce the environmental impact of their vehicles while optimizing component weight.

Applications of Rubber Calendering in EV Manufacturing

Rubber calendering technology plays a crucial role in several key areas of EV manufacturing:

Tires: Tires are one of the most critical components in the quest for lightweighting. Low rolling resistance is essential for maximizing the range of EVs. Calendered rubber allows tire manufacturers to create thinner yet highly durable tires, reducing overall weight while maintaining grip and performance.

Seals and Gaskets: The efficiency of an EV’s climate control system and noise insulation relies on high-quality rubber seals and gaskets. Calendered rubber enables the production of lightweight, effective seals that prevent air leaks and reduce noise pollution. These components also contribute to the vehicle’s aerodynamic performance, further supporting energy efficiency.

Electrical Insulation: Electric vehicles require high-quality electrical insulation to protect sensitive components like the battery and motor from moisture, dust, and other contaminants. Rubber calendering helps produce lightweight insulating materials that provide reliable protection without adding unnecessary weight to the vehicle.

Battery Components: As EV batteries become more advanced, the need for lightweight yet durable materials in battery insulation and housing increases. Calendered rubber can be used in the production of lightweight battery components that contribute to both the performance and safety of the vehicle.

Crowns Machinery: Driving Innovation in Rubber Calendering

Crowns Machinery is a leading manufacturer of advanced Rubber Calender Machines that are designed to meet the evolving needs of the EV industry. Their machines offer unmatched precision, durability, and flexibility, making them the ideal choice for producing lightweight rubber components.

Crowns Machinery’s Rubber Calender Machines are equipped with advanced features such as:

Precision Rollers: Ensure that each rubber sheet is calendered to the exact thickness required by EV manufacturers, enabling significant weight reductions without compromising performance.

Versatile Material Handling: Capable of processing a wide range of rubber compounds, including eco-friendly and recycled materials, which are increasingly being adopted by EV manufacturers to align with sustainability goals.

High Production Efficiency: Designed for continuous operation, these machines maximize output while minimizing waste, helping manufacturers meet the growing demand for lightweight EV components.

Crowns Machinery is committed to supporting the lightweighting goals of the EV industry, enabling manufacturers to produce high-performance, durable components that contribute to the overall efficiency and sustainability of electric vehicles.

The Future of Rubber Calendering in the EV Industry

As the demand for electric vehicles continues to rise, the importance of lightweighting will only grow. Rubber calendering technology, with its ability to produce precise, uniform, and lightweight rubber components, will remain a critical factor in this evolution. With innovations in material science and manufacturing processes, the potential for further reductions in EV weight is vast.

Crowns Machinery is at the forefront of these advancements, continuously refining their Rubber Calender Machines to meet the needs of the EV industry. By providing high-performance solutions for rubber component manufacturing, they are playing a key role in the global shift towards electric mobility.

Conclusion

Rubber calendering technology is revolutionizing the electric vehicle industry by enabling lightweight, durable, and efficient components that enhance performance while reducing weight. As EV manufacturers continue to prioritize lightweighting to improve vehicle range and efficiency, Crowns Machinery’s Rubber Calender will be a crucial partner in this journey. Their commitment to innovation and sustainability ensures that they remain at the forefront of rubber processing technology, helping the EV industry move towards a greener, more efficient future.

For more information on how Crowns Machinery’s Rubber Calender Machines can support your EV manufacturing needs, contact us today.