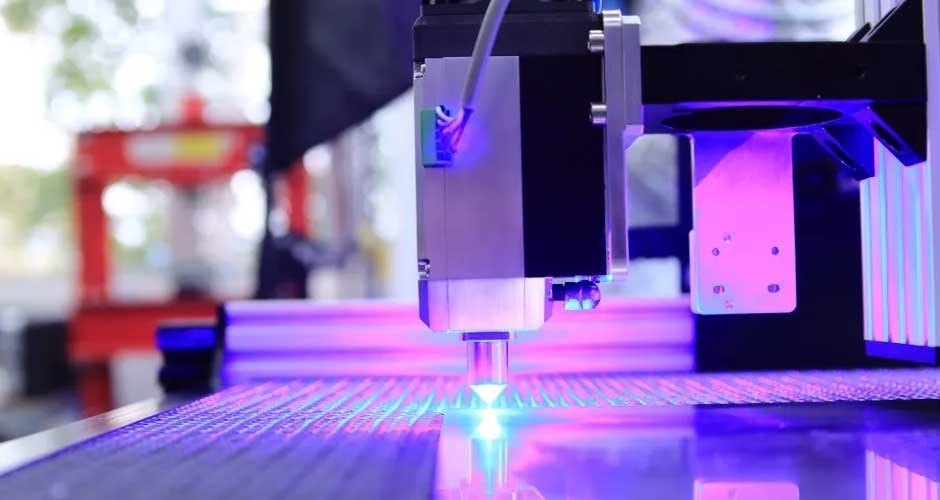

Laser engraving has become an essential technology for various industries, from manufacturing and automotive to jewelry and personalization services. The precision, speed, and versatility of laser engraving machines make them invaluable tools for businesses. However, choosing the right laser engraving machine can be challenging given the plethora of options available. This article explores the key elements to consider when selecting a laser engraving machine, helping you make an informed decision that meets your specific needs.

1. Type of Laser

Different laser types are suited for various materials and applications. The three primary types of lasers used in engraving are CO₂ lasers, fiber lasers, and diode lasers. Understanding their characteristics will help you choose the right one for your needs.

CO₂ Lasers

-

Best for: Non-metal materials like wood, acrylic, glass, leather, and plastics.

-

Advantages: CO₂ lasers offer high precision and are widely used due to their ability to engrave and cut a variety of non-metal materials.

-

Disadvantages: They are less effective on metals and generally require more maintenance than fiber lasers.

Fiber Lasers

-

Best for: Metals, including stainless steel, aluminum, gold, and silver.

-

Advantages: The best fiber laser cutting machines are highly efficient, have a long lifespan, and require minimal maintenance. They are excellent for high-precision engraving on metals.

-

Disadvantages: They are typically more expensive than CO₂ lasers and less effective on non-metal materials.

Diode Lasers

-

Best for: Marking on a variety of materials, including metals and some plastics.

-

Advantages: Diode lasers are compact, energy-efficient, and versatile.

-

Disadvantages: They generally offer lower power output and are not suitable for deep engraving.

2. Power and Speed

The power and speed of a laser engraving machine are critical factors that influence its performance and suitability for your projects.

Power

-

Measured in: Watts (W)

-

Impact: Higher power allows for deeper engraving and cutting thicker materials. However, higher power also typically means higher costs.

-

Consideration: Choose a laser power that matches your primary material and application needs. For example, a 40W CO₂ laser may be sufficient for engraving wood and acrylic, while a 50W or higher fiber laser may be necessary for metal engraving.

Speed

-

Measured in: Millimeters per second (mm/s) or inches per minute (ipm)

-

Impact: Faster engraving speeds increase productivity but may sacrifice some precision.

-

Consideration: Balance speed and accuracy based on your project requirements. High-speed machines are beneficial for large-scale production, whereas lower-speed machines might be better for detailed, intricate designs.

3. Work Area Size

The work area size of a laser engraving machine determines the maximum dimensions of the materials you can engrave. This is particularly important if you work with large items or need to produce multiple pieces simultaneously.

-

Small Work Area: Suitable for engraving small items like jewelry, nameplates, and small crafts.

-

Medium Work Area: Ideal for medium-sized projects such as plaques, awards, and signage.

-

Large Work Area: Necessary for large-scale projects or high-volume production, such as furniture components, large signs, and bulk items.

Consideration:

Evaluate your typical project sizes and production volumes to choose a machine with an appropriate work area size. A larger work area offers more flexibility but also comes at a higher cost.

4. Precision and Resolution

Precision and resolution are crucial for achieving high-quality engraving results, especially for detailed designs and fine text.

Precision

-

Measured in: Microns (µm)

-

Impact: Higher precision allows for finer details and sharper edges.

-

Consideration: If your projects require intricate details, such as in jewelry or electronics, choose a machine with high precision.

Resolution

-

Measured in: Dots per inch (DPI)

-

Impact: Higher resolution provides smoother gradients and finer details.

-

Consideration: For applications like photographic engraving or detailed artwork, a higher DPI setting is essential to capture fine details accurately.

5. Software Compatibility

The software that comes with or supports the laser engraving machine plays a significant role in the ease of use and capabilities of the machine.

Features to Look For:

-

User-Friendly Interface: Intuitive and easy to learn, reducing the learning curve and increasing productivity.

-

Design Capabilities: Ability to create, import, and edit designs within the software.

-

Compatibility: Supports various file formats such as DXF, AI, SVG, and BMP.

-

Advanced Features: Options for layering, variable engraving depths, and automation features for batch processing.

Consideration:

Ensure the software is compatible with your existing design tools and offers the necessary features to support your projects. Some popular software options include LightBurn, CorelDRAW, and Adobe Illustrator.

6. Maintenance and Support

Regular maintenance is necessary to keep your laser engraving machine running smoothly and to extend its lifespan.

Maintenance Considerations:

-

Ease of Access: Machines with easily accessible components simplify maintenance tasks such as cleaning lenses and mirrors.

-

Spare Parts Availability: Ensure that spare parts are readily available and affordable.

-

Support and Warranty: Choose a manufacturer that offers comprehensive support, including troubleshooting, repairs, and a warranty to cover defects and malfunctions.

7. Cost and Budget

The cost of a laser engraving machine can vary significantly based on its type, power, features, and brand. While it’s tempting to choose the cheapest option, it’s essential to balance cost with quality and features.

Considerations:

-

Initial Cost: Compare the initial investment with the machine’s features and capabilities.

-

Operating Costs: Consider ongoing expenses such as electricity, maintenance, and replacement parts.

-

Return on Investment (ROI): Evaluate how the machine will improve your productivity and quality, potentially leading to increased revenue.

8. Safety Features

Safety is paramount when operating a laser engraving machine. Ensure the machine you choose includes essential safety features to protect operators and the environment.

Key Safety Features:

-

Enclosed Design: Prevents exposure to laser beams and contains fumes and debris.

-

Fume Extraction System: Removes harmful fumes and particles generated during the engraving process.

-

Emergency Stop: Allows operators to quickly shut down the machine in case of an emergency.

-

Laser Safety Glasses: Protects eyes from harmful laser exposure.

Consideration:

Prioritize machines that comply with safety standards and regulations. Proper training and adherence to safety protocols are also crucial for safe operation.

Conclusion

Choosing the right laser engraving machine involves considering multiple factors, including the type of laser, power, and speed, work area size, precision, software compatibility, maintenance, cost, safety, and production control solutions. By carefully evaluating these elements, you can select a machine that meets your specific needs and enhances your productivity and efficiency.

Investing in a high-quality laser engraving machine tailored to your requirements will ensure that you achieve the best results for your projects, whether you’re engraving delicate jewelry, customizing industrial parts, or creating personalized gifts. With the right machine and tools, you can take your engraving capabilities to the next level, driving growth and success for your business.