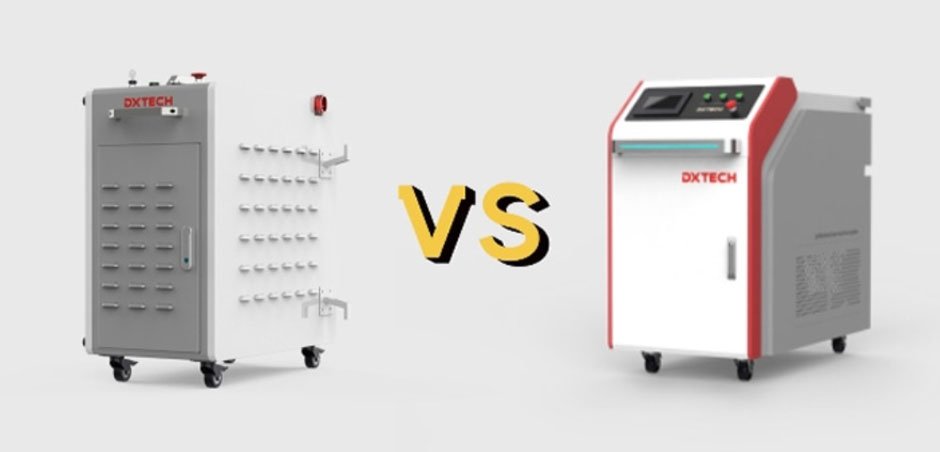

Laser cleaners use a laser to remove dirt, rust, or paint from surfaces. This is finished without the use of harsh chemical substances or detergents. There are fundamental varieties of laser cleaners: pulsed and non-stop laser cleaners.

These devices work differently. In this newsletter, we’ll explain the variations easily so you can understand what you would possibly want with a 1000W Pulse Laser Cleaning Machine.

What Is Laser Cleaning?

Laser cleaning is when a laser (mild beam) smooths something. The laser enables cast of dirt, rust, or paint without harsh chemical compounds. The laser heats the floor, causing the dirt to soften or fall or turn to dust.

Now, permits communication about two styles of laser cleaning gadgets: Pulse and Continuous.

What Is a Pulse Laser Cleaning Machine?

A pulsed laser cleansing tool works by sending short bursts of laser electricity. This blast is excessive and heats up quickly to cast off dust, rust, or paint and clean the surface.

Features of Pulse Laser Cleaning Machines:

High Strength: Laser bursts are intense and perfect for cleansing cussed dirt or rust.

Accuracy: The laser is centered and can sweep a small or colossal place.

Quick: Explosions are brief, after which they clean the surface in a short period.

Excellent for competitive cleansing: Ideal for complicated jobs like removing rust or old paint.

Interest:

Cleans complex surfaces: A strong blast can easily rust or heavy paint.

Deficiency Disadvantage: The laser works briefly, so it no longer harms the surface.

Ease of Maintenance: The equipment does not need to be on constantly, so it is simple to maintain.

Mistakes:

It takes longer: If the device is more significant, it may need to enter the web page as soon as possible.

It may be hard to apply: It can be challenging to use on massive pages or pages with many exceptional dimensions.

What Is a Continuous Laser Cleaning Machine?

A Continuous Laser Cleaning Machine works by sending out a consistent laser beam that remains on all the time. This laser acts over the surface and cleans it without preventing it, unlike a 300W Pulse Laser Cleaning Machine.

Features of Continuous Laser Cleaning Machines:

Always-On Laser: The laser stays on and continues cleaning the surface.

Oven Cleaning: The laser offers a regular and clean easy.

Suitable for Big Areas: The laser works quicker on more significant regions because it no longer stops.

Advantages:

Fast for Large Areas: It is quicker for cleaning huge areas.

Smooth Cleaning: The cleansing is clean and even across the surface.

Easy to Use: Flow the device, and the laser continues working.

Disadvantages:

Not as Precise: The laser stays on constantly, so it’s more challenging to smooth small or delicate spots.

Can Cause Heat: Since the laser is always on, it can create heat that would harm the floor.

Not Best for Tough Jobs: It might not paint as properly for cleansing heavy rust or paint.

Key Differences Between Pulse and Continuous Laser Cleaning Machines

Here is a table to simplify the difference between the two styles of lasers.

Features Pulse Laser Cleaning Machine Continuous Laser Cleaning Machine Laser Type Small burst of electricity (pulse)Steady, non-stop laser beam pace Slow for massive areas but very accurate Fast for large areas but not low accuracy AccurateAccuracyAccuratevery very cautious sidestep accurate, accurate for trendy cleaning energy consumption more strength -green for hardcore jobs more Uses strength due to the fact it is continually onRisk of Heat DamageLess warmth DamageHigh heat can build up and harm the wallBest to easy rust this is tough, and paint cleans large regions quicklyCleanupEasy to maintain needs more care since it runs usually

When should pulse laser cleaning generation be used?

Pulse laser cleaning machines are ideal for cleansing stubborn stains like rust or antique paint. They are excellent for unique cleansing in small and huge spaces. If you want to clean something that calls for extensive protection, a pulse laser is the best alternative.

Examples:

Washing of non-corrosive steel parts containing non-ferrous metallic.

Paint removal from antique machines.

When to Use Continuous Laser Cleaning Machines?

Continuous laser cleaning machines are higher for cleaning big surfaces speedy. They paintings properly whilst you need to smooth huge regions speedy. The steady beam makes it clean and straightforward without stopping.

Examples:

Cleaning large machines quickly.

Preparing massive steel surfaces for extra paintings or portray.

Conclusion

Both Pulse Laser Cleaning Machines and Continuous Laser Cleaning Machines are beneficial, however they work best in one of a kind situations.

If you need precision and are cleansing tough dirt like rust or antique paint, the heartbeat laser is the pleasant preference. It is strong and works appropriately for demanding jobs.

If you want to easy massive regions quickly and don’t need to be as particular, the continuous laser is a higher desire. It works speedy and is less complicated to apply for big surfaces.

Think about what you need to clean, how huge the region is, and how difficult the dust is. This will help you select the proper device for the job.