Have you ever wondered how complex metal parts are made so precisely and efficiently? In metal parts manufacturing, casting plays a vital role in turning raw materials into intricate, high-quality products.

Whether you’re involved in manufacturing or just curious, understanding these key roles can help you appreciate the importance of casting in shaping the metal industry today.

Complex Shapes

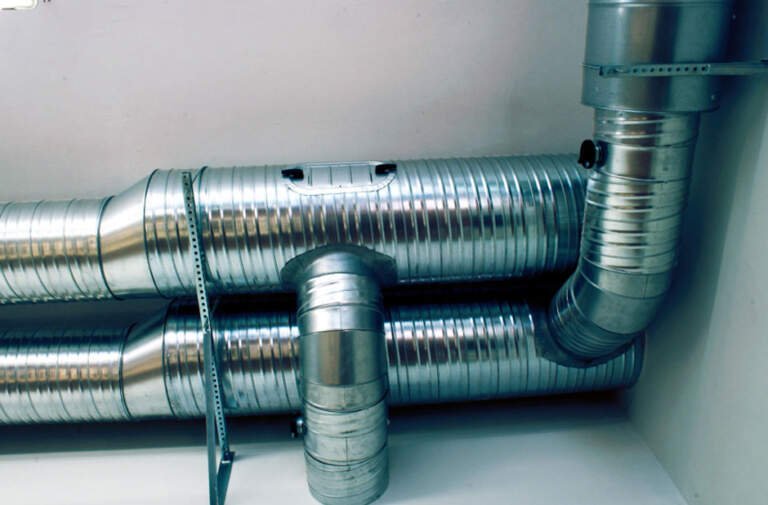

Casting is a useful method for creating parts with complex shapes. It allows for the production of intricate designs that may be too difficult for other methods to handle. This is important for industries that require detailed components with specific features.

The molds used in casting can be made in many different forms to accommodate unique part designs. This reduces the need for additional processes like welding or assembly. As a result, casting simplifies the production of complex parts.

For example, an investment casting foundry in Utah can create highly detailed metal parts for industries such as aerospace and medical devices. This process enables the production of intricate components that meet strict requirements.

Material Efficiency

Casting can make the most of the material used by reducing waste. The molten metal fills the mold, ensuring minimal scrap material. This is particularly useful when working with expensive metals or alloys.

With casting, manufacturers can reuse scrap material in the production process. This helps lower costs and increases the sustainability of production. Casting techniques also allow for more efficient use of raw materials, further reducing waste.

Cost-Effectiveness

Casting is a cheap way to make metal parts, especially when a lot of them need to be made. Since the molds are already made, making a lot of parts doesn’t cost much more per unit. Casting is great for businesses that need a lot of parts quickly because of this.

The process also cuts down on steps that require a lot of work. Less work needs to be done by hand because the molds do a lot of the work. This lowers the general cost of making things and speeds up the process.

High Degree of Precision

These days, casting methods can make the end product very precise. These methods, like investment casting, can make parts that are very exact in terms of their sizes and tolerances. This means that less cutting or adjusting is needed.

Being able to make things with great accuracy also means that they will work better and last longer. Precision-made parts fit together better and work the way they’re supposed to.

Design Flexibility

Casting gives designers a lot of freedom, so companies can make a lot of different parts. You can make things that are big or small, and they can have different weights and sizes. This adaptability is very important for businesses whose product needs change often.

When engineers use casting, they can make things with specific features and shapes to meet needs. The process can work with plans that might not be possible with other ways of making things. Because of this, casting is a flexible choice that can be used in many situations.

Unlock Precision and Efficiency in Metal Parts Manufacturing With Casting

Casting plays a vital role in metal parts manufacturing by offering efficient solutions for producing complex and precise components. Its ability to reduce material waste and lower production costs makes it a preferred method in many industries.

Overall, casting is essential for creating high-quality metal parts. Its advantages make it an important process in modern manufacturing.

Did this article expand your knowledge? If so, don’t forget to visit our blog for further educational material.